I have now completed week four of eight weeks of the

Second Annual International Winter Layout Party on

TrainBoard. Progress continues on the Emerson, GA scene of the layout as shown in the series of photos below.

I had originally planned on using 2" thick extruded foam board in the town of Emerson, including the roadbed for the Emerson house track. However, after some foam board experiments did not yield satisfactory results, I decided to stick with my spline roadbed/cardboard web combination. This meant that before I could continue the cardboard web in town, I had to (finally) build the roadbed for the Emerson house track. Up until now, the diverging route of the turnout from the siding to the house track was just floating in space like a track to nowhere.

When I went to start work on the roadbed for the house track, I noticed about a foot of the passing siding track had popped loose from the roadbed and was just floating about 1/4" in the air. For most of 2009, the Atlanta area was innundated with record shattering rainfall. However, for the last several weeks, we have been having bitterly cold and extremely dry weather. This has caused the benchwork to dry out and the resulting "shrinkage" has caused a lot of track pops. Usually just a few drops of super glue will tack the track back down nicely, but this particular section of the passing siding near the house track was extreme and required some special attention.

» Photos

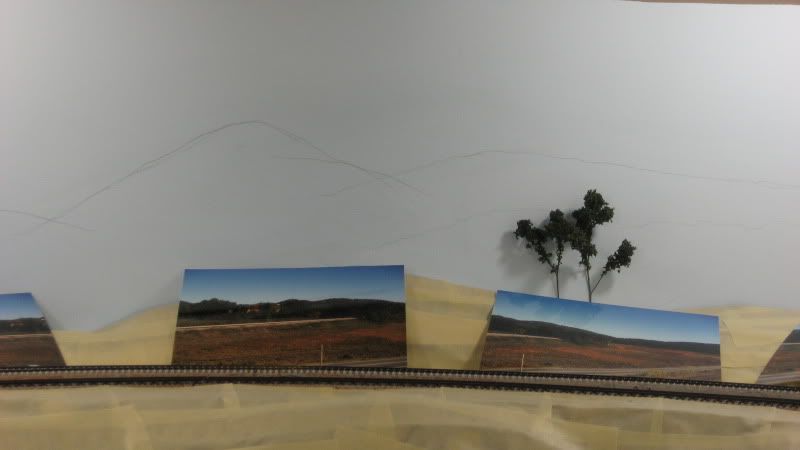

Here is a profile photo of the siding track that has popped up in Emerson. The cutting mat in the background shows the scale of the deformation:

Here is a wider angle shot of the same track with the cutting mat removed:

Fortunately, this section of flex track terminates at a turnout and I do not solder any rail joiners on my turnouts. This allowed me to slip the rail joiners back, lift up the flex track, and nip a bit off the ends of the rails. This allowed the track to conform to its original alignment. I then placed the track back down and slid the rail joiners back into place. I have left gaps between the ends of the rails here to allow for more expansion in the future:

After shortening the track and joining it back to the house track turnout, the track gang laid a bead of super glue and placed some clamps to get the track attached back to the roadbed:

A test train crawls across the newly repaired trackwork:

To prevent track pops from happening, I gap every section of flex track. However, in this closeup photo, you can see that the extreme benchwork shrinkage has completely closed the gaps in both rails (just to the left of the feeder wires), causing the track pop that was repaired above:

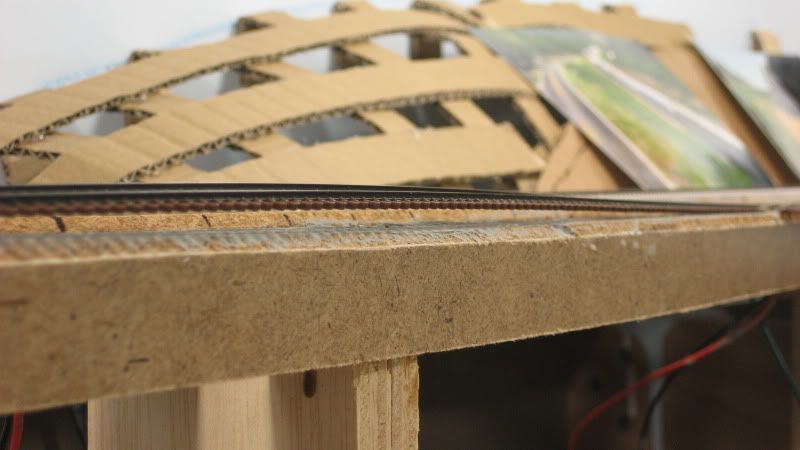

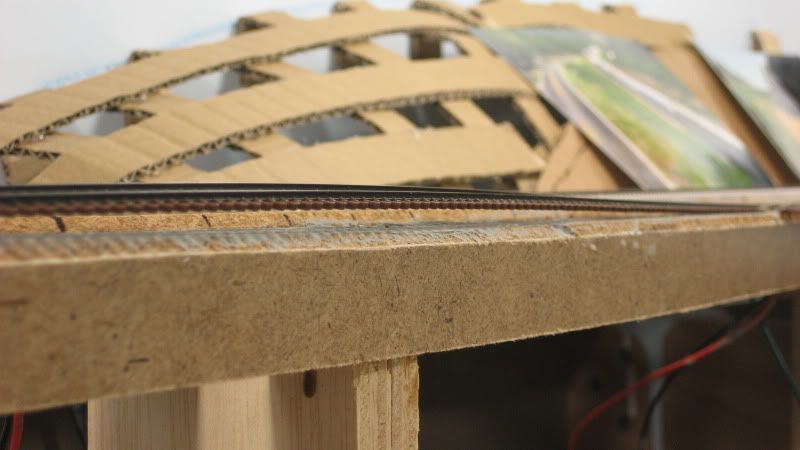

With the popped trackwork repaired, I moved on to building the roadbed for the Emerson house track. Here are the first few splines clamped in place:

Spline roadbed goes together quickly. A few hours after starting, the spline roadbed for the Emerson house track has been completed:

The Emerson house track is used for setting out defective cars and has a capacity for three 50-foot cars:

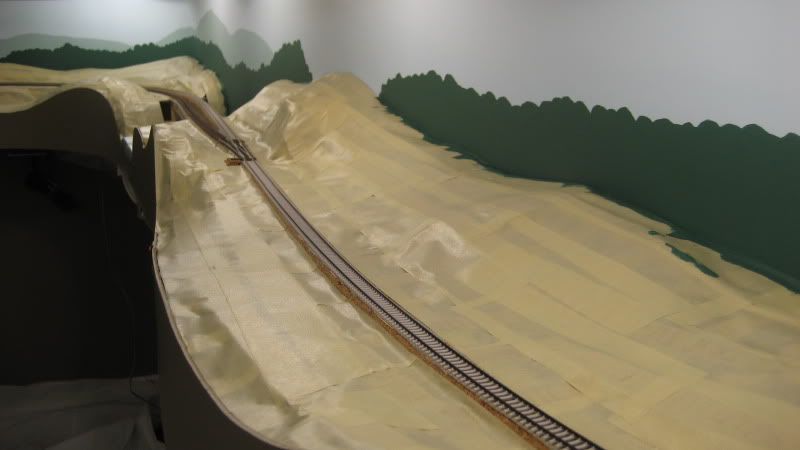

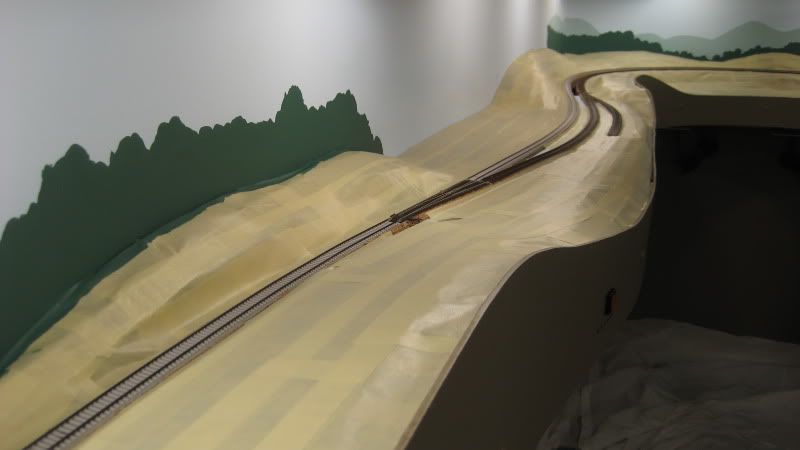

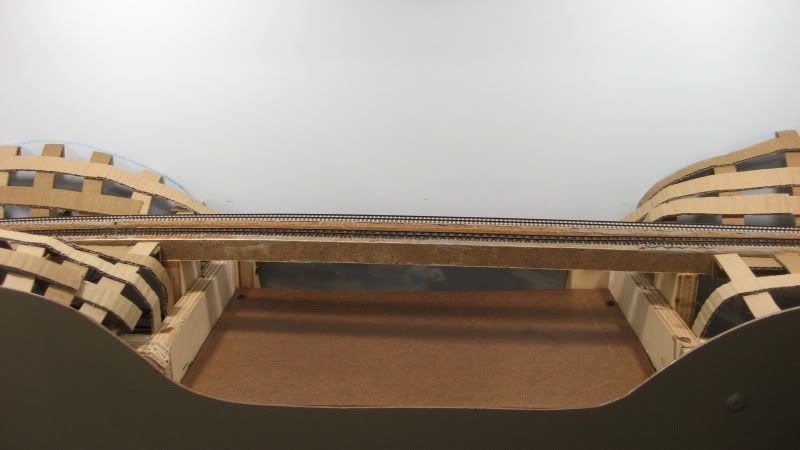

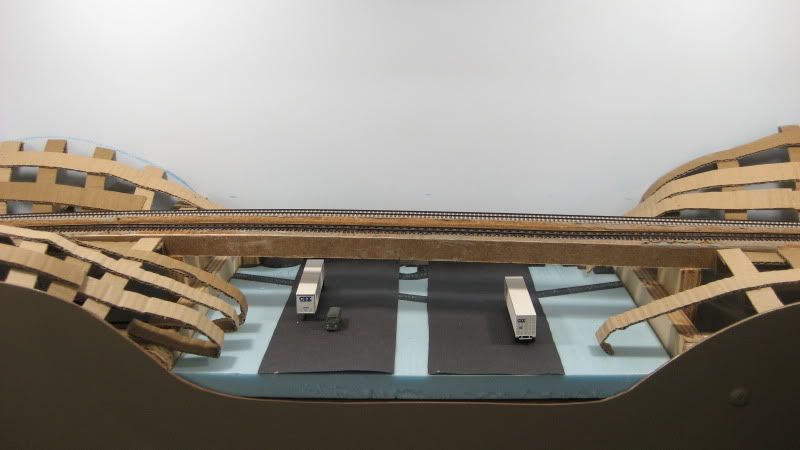

Finally, I completed the cardboard web between the tracks and the backdrop all the way to the north end of the Emerson scene. The flat area in the middle distance is to accomodate a residential neighborhood that borders the railroad:

Here is the same area looking north:

.