The CSX W&A subdivision crosses the Etowah River in scenic Bartow County, Georgia about 40 miles northeast of downtown Atlanta. This location has great sentimental value to me because it was the first location I railfanned with my family when I was seriously getting into the hobby back in 2007. The photo above was taken by Patrick Phelan (via RailPictures.net, used by permission) and led me to explore the area in the first place. I have it taped to the fascia on the layout to use as motivation for bringing this scene to life.

» The Prototype

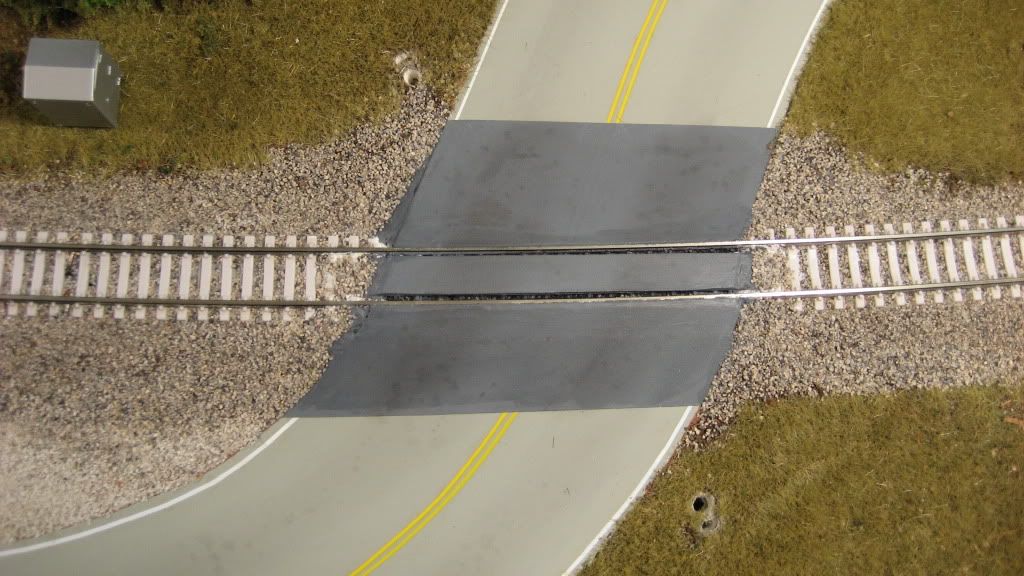

The prototype bridge is a seven-span ballasted deck girder bridge. The bridge crosses not just the Etowah River, but also Old River Road, which runs along the banks on the north side of the waterway. The approaches to the bridge are built on a high fill that is completely covered in a layer of lush Georgia kudzu. Most of the surrounding area is rural, with a low-lying pasture featuring a picturesque red barn located along the north shore along Old River Road.

The basic bridge construction is fairly typical: a ballasted deck made of railroad timbers laid across a pair of steel plate girders, which in turn rest upon tapered concrete piers. Some of the unique features of the bridge include a cableway running along the west side of the girder face, grab irons mounted on the west faces of the piers, and the lack of any railings or walkways. At one time, ladders extended to the bridge deck from the tops of the piers, but at some point these were cut free and left hanging off the top of the piers. Given the lack of railings and walkways, I would be interested in knowing what happens when a conductor must walk a train stopped across the bridge.

Photos below by Kenny Shackleford via Flickr, used by permission.

» The Model

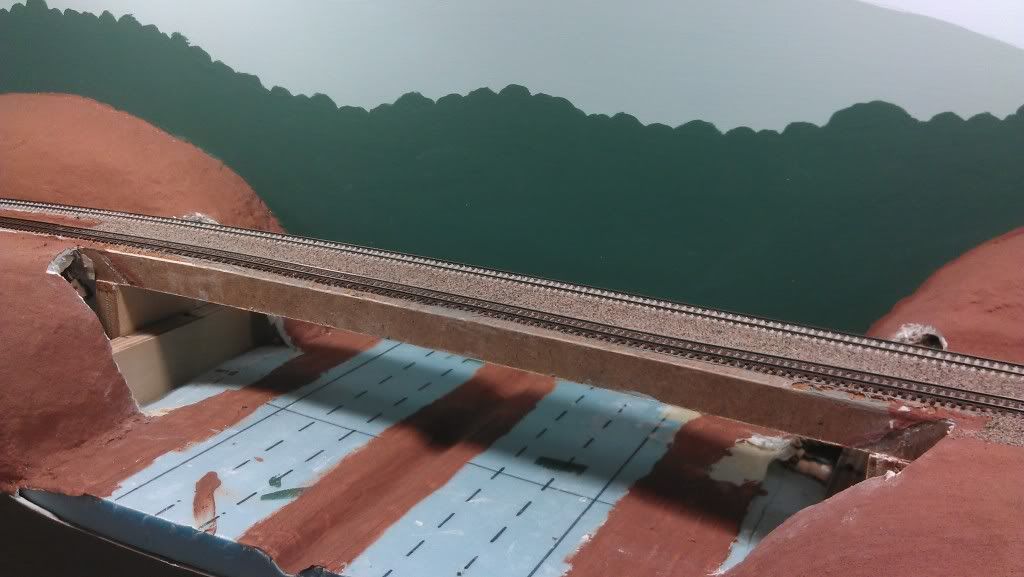

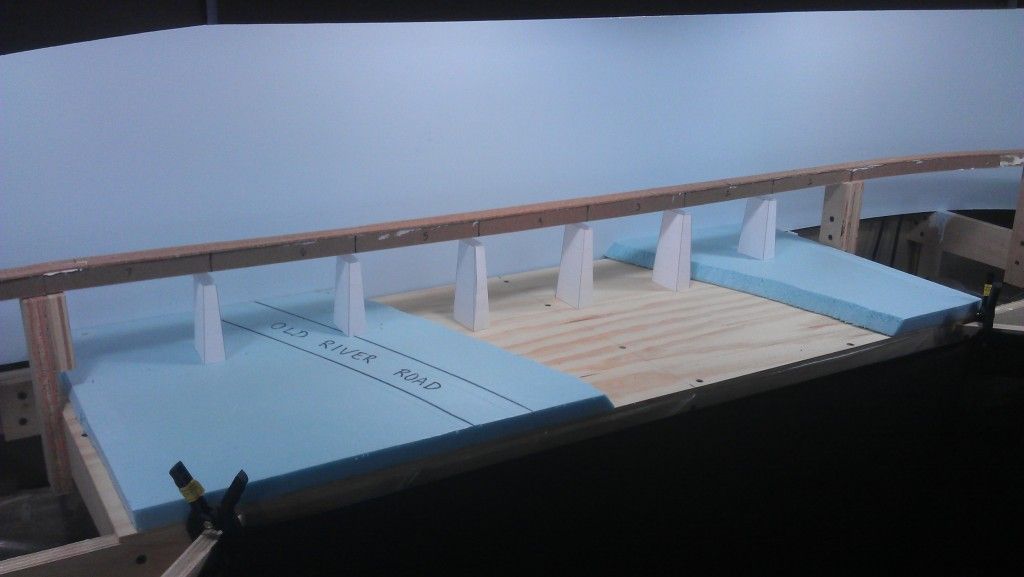

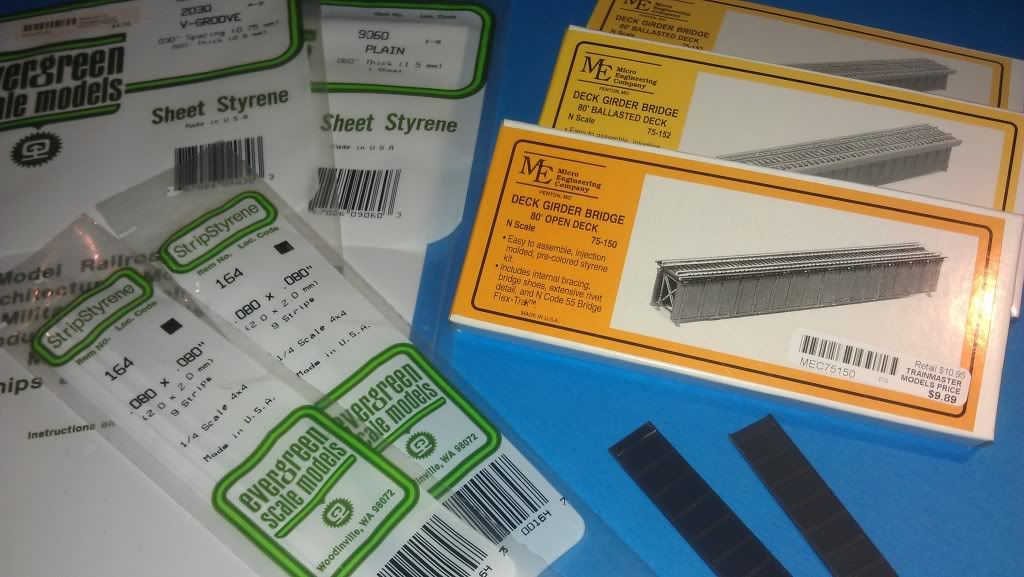

The model bridge will also be a seven-span ballasted deck girder bridge as mocked up in the photo below. The bridge itself will be kitbashed from seven Micro Engineering 80' deck girder bridges. The girders from the kits will be used, while the deck will be scratchbuilt. The piers and abutments will be cast in plaster using scratchbuilt molds. The bridge must be constructed so that the top of the deck lines up with the top of the spline roadbed approaches. This will allow cork roadbed, track and (eventually) ballst to be laid across the bridge and approaches in a continuous manner. My standard cardboard web, plaster cloth and Sculptamold terrain will be used to simulate the high fill found on the prototype. Finally, the surface of the plywood riverbed will be sanded and painted, then covered with Envirotex to simulate the water. The Etowah consistently has a deep green color in this area and is often quite calm, so the Envirotex should do an excellent job of simulating the river in this scene.

The next posts in this series will chronicle the construction of the Etowah River bridge on the layout over the coming weeks.

.