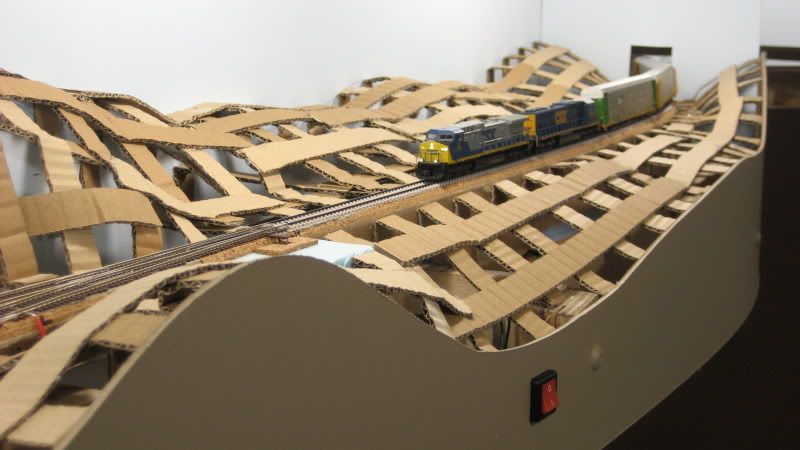

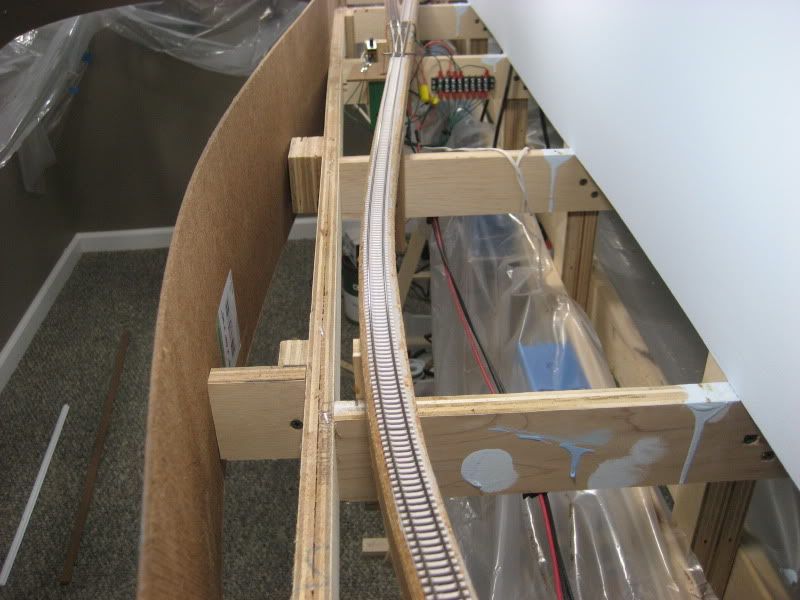

After an extended time away from the layout due to work, family, and a bout of temporary insanity while I considered switching locales, railroads and eras, construction has resumed on the N-scale CSX Dixie Line layout. I have decided to move forward with construction in the town of Emerson, GA even before the trackwork has been completed on the rest of the layout. This weekend, I completed all of the fascia in this section of the layout.

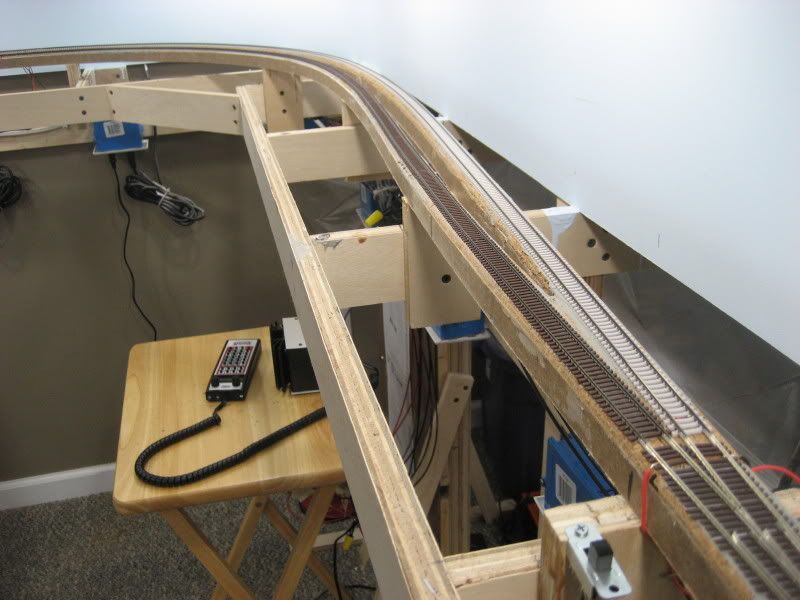

Before installing the fascia, I had to add some supports along the front of the layout where the scenery will extend a bit into the aisle. While the construction worked out just fine, I discovered that extending the layout in this manner really encroaches on aisle space. Even though I only extended a mere 3" into the aisle at two points, I found that my aisle that was comfortably wide at 30" is not so comfortable at 27". While I never had a problem with aisle width before, now I find myself brushing against the new fascia from time to time in the two spots where it bows out into the aisle. All of my controls will be recessed so I do not anticipate any problems, but I have learned my lesson well and from now on the aisle boundaries are off limits for expansion.

» Photos

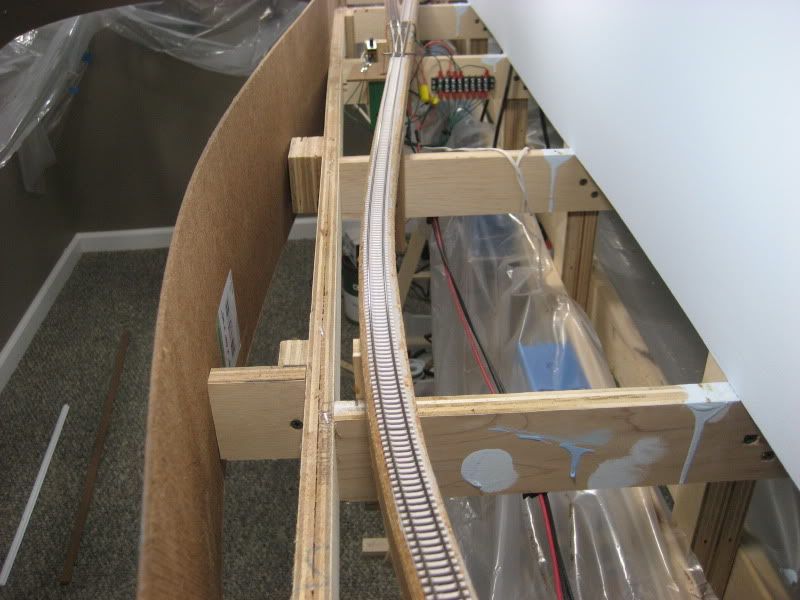

In this picture, you can see how I used 8" wide strips of hardboard screwed to the front boards of the benchwork. The hardboard extends 1" below the front boards. You can also see where I have drawn the profile of the hills using blue chalk:

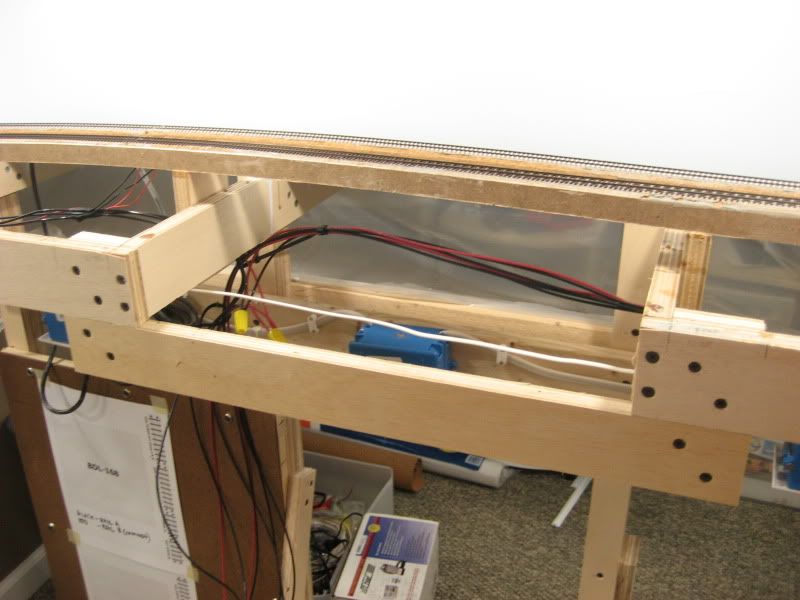

These two views show how the fascia bows away from the benchwork in two locations where the layout was extended into the aisle. Note the special brackets used to support the fascia in these areas:

Finally, I used a sabre saw fitted with a metal cutting blade to cut the hill profiles on the fascia:

The gaps in the fascia where two pieces of hardboard meet will be filled by panel molding strips and will blend in nicely once everything gets primed and painted. I also need to go back and redo some of the screws holding the fascia on to the benchwork. A few of these are not in a straight line as you can see in one of the above photos.

The cutting activity caused a lot of vibration in the layout, as I rattled an autorack right off a staging track a good 8 feet away from where I was cutting. I also found a few sections of track that separated from the caulk holding it to the roadbed. Also, the fine sawdust managed to gunk up the track and fouled a Kato locomotive, even after I thought I had removed all of the dust with a Shop Vac. For future cuts, I will remove the fascia boards after drawing the hill profile in chalk and make the cuts in the workshop.

.