I also accomplished a few other significant tasks this week. First, I settled on a method for superelevating the mainline curves on the layout. The technique I am using to superelevate curves was published in Model Railroader and recommended by several members on Trainboard. I posted a detailed step-by-step article on how I superelevated the first mainline curve on the layout. Next, I devised a near goof-proof method for soldering feeder wires to my flextrack. Considering that each piece of flextrack will need a pair of feeders and my soldering skills leave much to be desired, this was a very important accomplishment. Again, I posted a detailed step-by-step article on how I solder the feeder wires to the flex track. Finally, I decided to use Micro Engineering flex track for all of my trackwork. I have always used Atlas flextrack in the past and really like their code 55 offering, but I purchased some Micro Engineering track because it was the only product available with concrete ties. After working out some kinks with the Micro Engineering flextrack (literally!), I have decided that I really like the stuff and will be using it entirely on the layout, not just in the areas where CSX employs concrete ties. The upcoming weeks call for completing the trackwork in the Emerson area of the layout. This will require a lot of soldering, track bending and caulking, but after running that first train, I can say the results are well worth the effort!

Photos

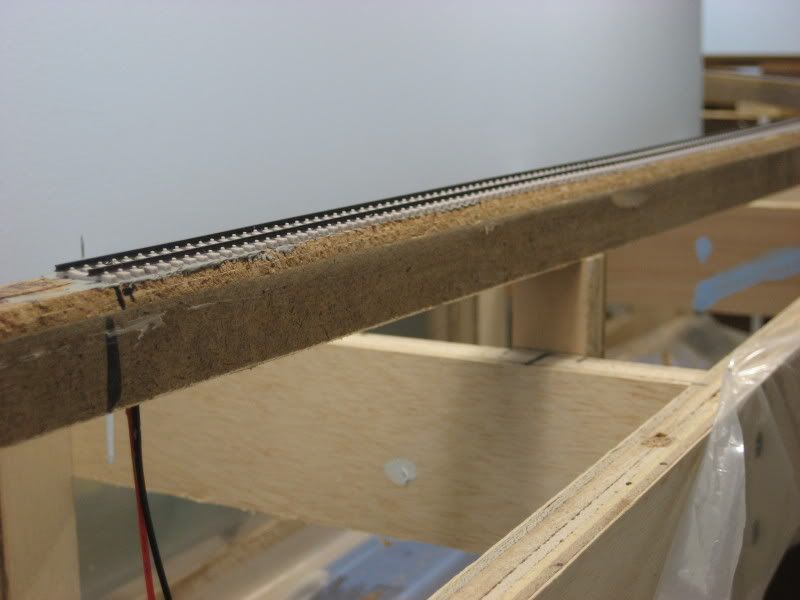

First section of Micro Engineering code 55 concrete tie flex track installed immediately south of the turnout for the south end of the Emerson passing siding. All track is attached using grey DAP acrylic latex caulk. The clamps are very loosely secured just enough to hold the track down while the caulk sets up:

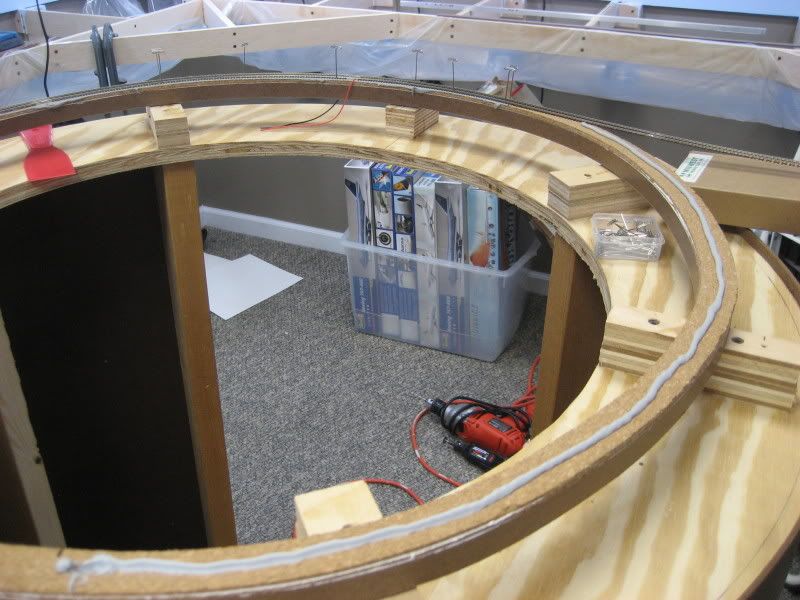

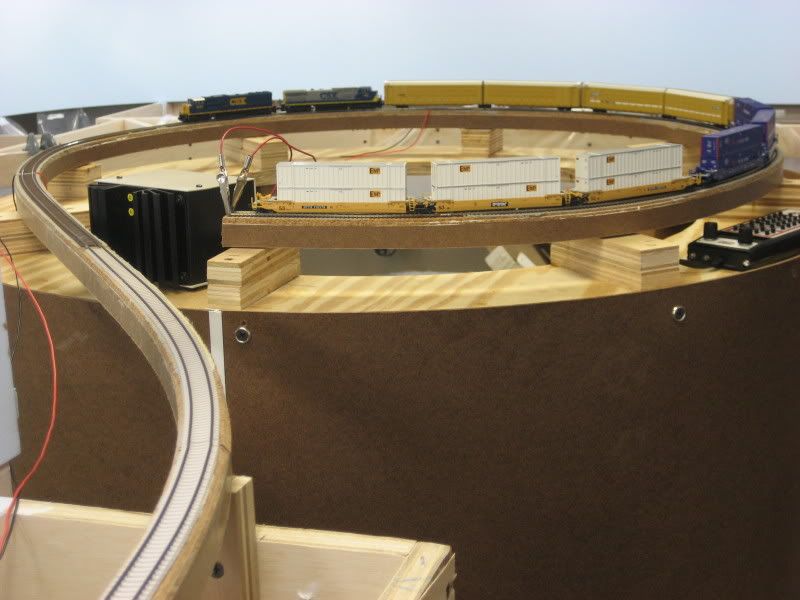

Laying the Atlas code 55 flex track in the temporary staging area built where the future helix will be located. The first picture shows the bead of caulk laid down, the second picture shows the track pressed into the caulk and held in place with T-pins. These pins are probably not necessary since the caulk has a lot of grab to it. In fact, the entire section of springy flextrack (which is along a tight 15" radius curve here) was held in place just fine by the caulk alone, but I added the T-pins just in case:

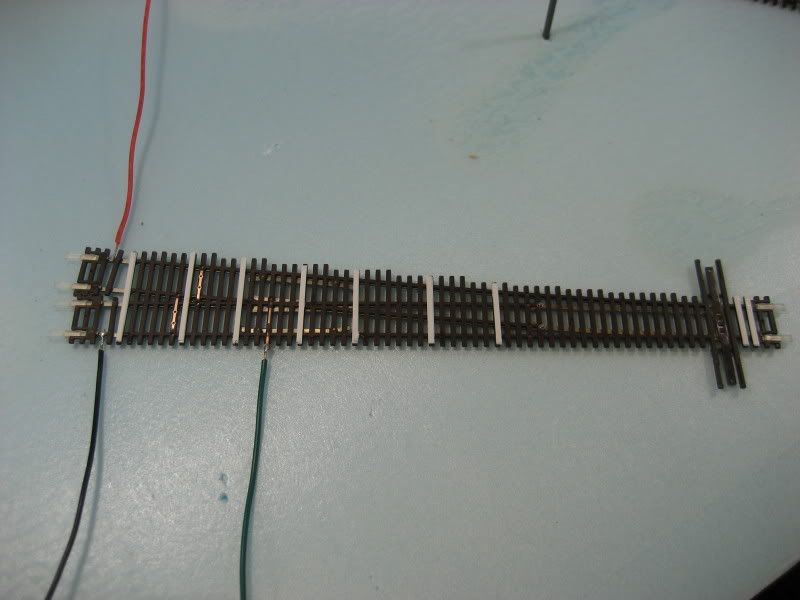

Here is the first turnout to be installed, which is an Atlas code 55 #10 turnout at the south end of the Emerson passing siding. I will be using a computerized CTC system, so each turnout will be its own detection block (aka a control point). As such, the turnouts will have insulated rail joiners all around and needs its own set of feeders. You can see where I have soldered the red and black feeders at the frog end of the turnout; the green wire is used to power the frog and will get the appropriate polarity from the auxiliary contacts of a Tortoise turnout motor. You can also see where I have glued strips of .020" styrene to the bottoms of some of the ties on the turnout. This is necessary because the height of ties on the Atlas code 55 track is about .020" shorter than the ties on the Micro Engineering track:

On this photo of the photo of the installed turnout, you can see the temporary bus wire that I installed so that we could run a train over the new trackwork. The turnouts are affixed with the same latex acrylic caulk used for the flextrack. Notice how no caulk is used anywhere near the moving points of the turnout:

Finally, a few overviews showing all of the completed trackwork. Including the temporary staging area, about 16' of track has been permanently installed. Here is the completed visible mainline at South Emerson:

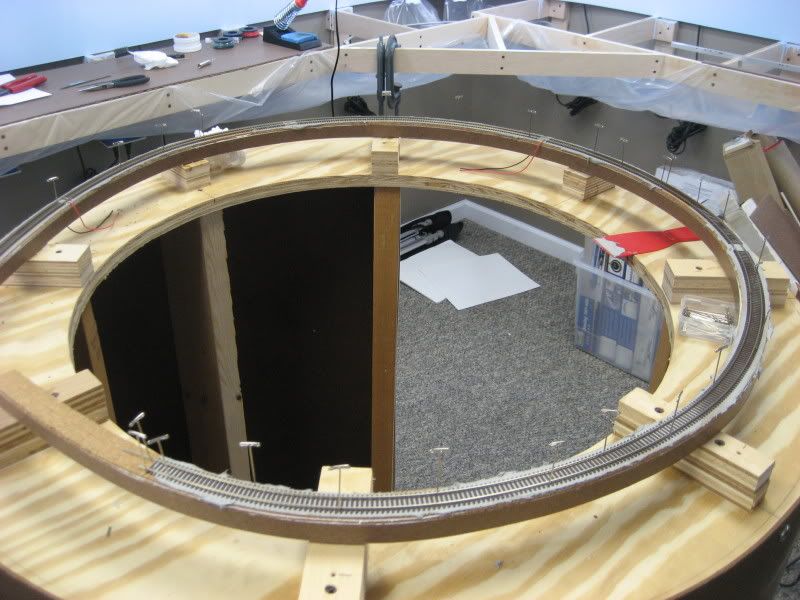

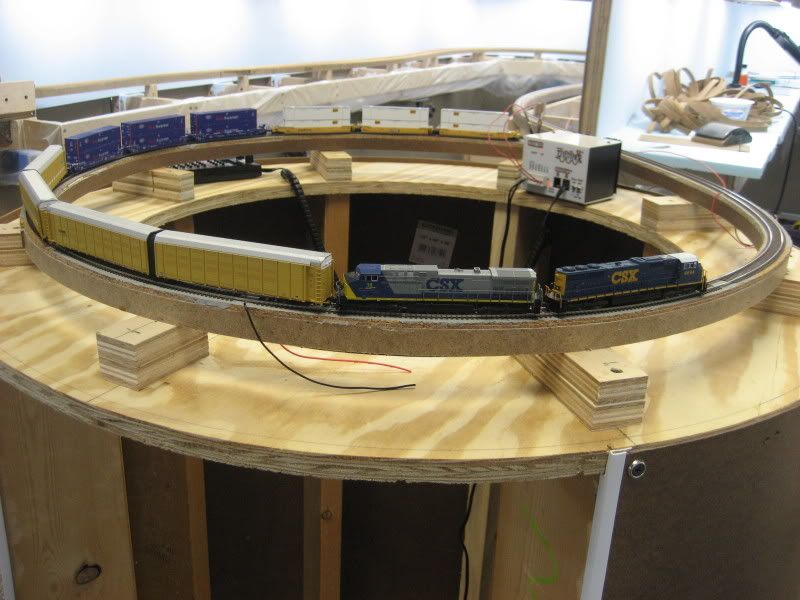

Completed temporary staging track:

.